Prototech manufactures reception, storage and control systems designed in accordance with the customers’ needs and which are technologically suitable for handling the various types of products delivered by tanker (milk, cream, fruit puree, preserves, eggs, water, sugar, liquid and powder ingredients, etc.) or individual tanks and then stored in appropriate containers.

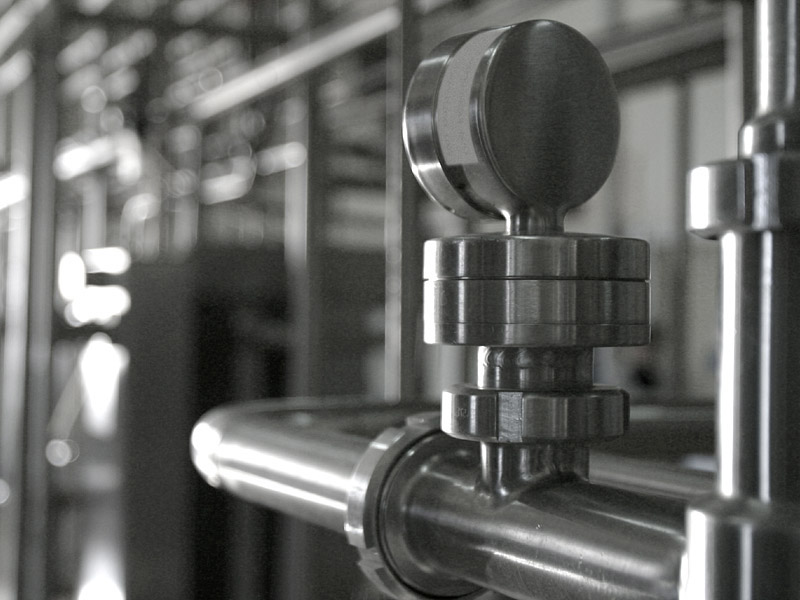

The systems are usually made entirely of stainless steel, and are equipped with all the necessary equipment for unloading, de-aeration, cooling and cleaning, and can also be supplied as pre-assembled units on a platform.

When designing and building the equipment, Prototech's engineers pay particular attention to the physical, chemical and organoleptic properties of the incoming products in relation to the materials employed and their finishing (the degree of internal polish of the stainless steel piping, the welding, the valves, control and management instruments, etc.).

The plant can be supplied by Prototech on a turn-key basis or built as a subproject with the direct supply of certain components such as stainless steel storage tanks by other qualified partners. The plant is equipped with management and control systems for incoming products, which can also be supplied as stand-alone systems or integrated into the process management system. The particular competence and professionalism of both our designers and installers guarantee perfect functionality in compliance with 3A Standards and Good Manufacturing Practice.